Serviços Personalizados

Journal

Artigo

Indicadores

-

Citado por SciELO

Citado por SciELO -

Acessos

Acessos

Links relacionados

-

Similares em

SciELO

Similares em

SciELO

Compartilhar

Ciência e Técnica Vitivinícola

versão impressa ISSN 0254-0223

Ciência Téc. Vitiv. vol.27 no.1 Dois Portos 2012

Volatile compounds from oak, cherry, chestnut and acacia chips: influence of toasting level

Composição volátil de aparas de carvalho, cerejeira, castanheiro e acácia: influência do nível de queima

Nuno Martins1, Raquel Garcia1, Marco Gomes Da Silva3, Maria João Cabrita1,2*

1 Instituto de Ciências Agrárias e Ambientais Mediterrânicas (ICAAM), Universidade de Évora, Portugal.

2 Departamento de Fitotecnia, Escola de Ciências e Tecnologia, Universidade de Évora, Ap 94 7002-554, Évora, Portugal.

3 REQUIMTE, Departamento de Química, Faculdade de Ciências e Tecnologia, Universidade Nova de Lisboa, 2829-516 Caparica, Portugal.

SUMMARY

In the present study, the volatile composition of wood chips from several botanical species potentially relevant for oenological purposes, namely acacia (unknown specie), chestnut (Castanea sativa), cherry (Prunus cerasus) and oak (Quercus robur) was studied by GC/MS. In order to evaluate the effect of the toasting process on volatile compounds contents we have extended our study to wood chips from the botanical species described above, subjected to different toasting levels, such as untoasted and medium toast. To achieve this goal, a preliminary step comprising the extraction of the volatile compounds by pressurized liquid extraction (PLE) has been performed followed by the analysis and identification of those compounds by GC/MS. The identification was tentatively achieved attending to the characteristic fragmentation patterns of these compounds and by comparison with those reported in the literature. The determination of linear retention indexes has allowed the confirmation of those attributions. Within this study, we were able to identify 45 compounds, arising from polysaccharides, lipids, lignin and polyphenols degradation. Additionally, 16 other compounds were identified in the different wood species under study although their origin is not fully known. In general, our results showed differences among the volatile composition of the different botanical species studied in this work and the influence of toasting degree was also observed in this study.

Key words: wood chips, volatile compounds, PLE, GC/MS.

RESUMO

No presente estudo, os compostos voláteis de aparas de madeira de diferentes espécies botânicas potencialmente relevantes em enologia, acácia (espécie desconhecida), castanheiro (Castanea sativa), cerejeira (Prunus cerasus) e carvalho (Quercus robur) foram estudados por GC/MS. De forma a se poder avaliar o efeito da queima no teor em compostos voláteis, este estudo foi também efectuado em aparas de madeira das espécies acima indicadas, sujeitas a diferentes níveis de queima: não queimadas e queima média. A primeira etapa deste estudo consistiu na obtenção dos compostos voláteis das amostras em estudo por extracção com solvente pressurizado (PLE), seguida da análise dos extractos obtidos por GC/MS. A identificação dos compostos foi efectuada por comparação com os padrões de fragmentação dos compostos em estudo, por comparação com os referidos na literatura. A determinação dos índices de retenção linear permitiu a confirmação da identificação. Foram identificados 45 compostos, provenientes da degradação dos polissacarídeos, lipídos, lignina e polifenóis. Foram ainda identificados 16 compostos, embora a sua origem não seja totalmente conhecida. Os resultados demonstram que as diferentes espécies botânicas em estudo apresentam diferenças na composição volátil. O efeito da queima na composição volátil foi também observado.

Palavras-chave: aparas de madeira, compostos voláteis, PLE, GC/MS.

INTRODUCTION

After an extensive research on volatile compounds of oak, researchers are now interested in other wood species, namely chestnut, acacia and cherry. The increasing interest on other woods than oak are linked to the possible use of wood fragments instead of barrels.

Botanical species and technological treatments during cooperage such as seasoning and toasting, plays a relevant role in final volatile composition of woods (Chatonnet and Dubourdieu, 1998; Canas et al., 1999; Cadahía et al., 2001; Doussot et al., 2002; Pérez-Prieto et al., 2002; Cadahía et al., 2003; Arfelli et al., 2007; Canas et al., 2011; Alañón et al., 2012). The main botanical species used in cooperage is oak (genus Quercus) and in a lesser extension, chestnut (genus Castanea). The oak species more used in cooperage are Quercus alba (American oak), Quercus patraea Liebl. (sessili oak), Quercus robur L. (pedunculate oak) and Quercus pyrenaica. In 2005, OIV approved (Resolution Oeno 3/2005) the use of oak and chestnut wood fragments, like chips and staves. Then, researchers were looking into other kind of woods which were abandoned in the past due to the lack of cooperage properties. The chemical compounds released from acacia, chestnut, cherry, mulberry and oak untoasted woods into alcoholic extracts, shows that each wood has a different and characteristic volatile compound profi les (Flamini et al., 2007, Rosso et al., 2009, Fernández de Simón et al., 2009b).

Among all variables that can influence wood characteristics and their impact on wine or spirits sensory changes, heating is the most important. Toasting has a signifi cant influence on wood’s chemical compounds, modifying both the quantity and the quality of the extractable substances (Cutzach et al., 1997; Chatonnet, 1999). The toasting process drastically enhances the gain in volatile compounds arising from the thermal degradation of oak wood (Cutzach et al., 1997; Chatonnet, 1999; Doussot et al., 2002), so it is expectable the same influence on other wood species. The extent of the chemical changes during thermal treatment depends considerably on the chemical structure of the wood species apart from many other factors, such as the type and the duration of thermal treatment (Windeisen and Wegener, 2008).

When heat is applied to wood during toasting process, chemical bonds are disrupted within biopolymers such as cellulose, hemicellulose, lignin, polysaccharides, polyphenols and lipids, resulting in degradation or compositional changes by pyrolisis and thermolysis (Fernández de Simón et al., 2009b; van Jaarsveld et al., 2008), which induce a notable modifi cation of wood chemical composition.

Volatile phenols, phenolic aldehydes, phenyl ketones and some phenyl alcohols are mainly formed from lignin thermodegradation. In particular, high levels of mono and dimethoxylated phenols, benzoic and cinnamic aldehydes were identified in toasted wood. Lignin is a complex polymer synthesized from phenylpropanoid monomers, and with thermal processing yields a range of products, of which the most characteristic ones are methoxy phenols (Asghari and Yoshida, 2010).

Heat degradation of polyosides leads to the production of furanic aldehydes, pentacyclic and hexacyclic ketones. Lactones, formed from wood lipids, increase their concentration at the beginning of toasting, although they can be destroyed by a lengthy toasting process (Giménez-Martínez et al., 1996; Chatonnet, 1999; Cadahía et al., 2003). This thermo degradation process leads to the formation of several compounds that can be transferred to wine and spirits during aging or maturation, hence, extensive information about the volatile composition of wood used in cooperage would be of great interest to the wine industry.

In order to study volatile fraction of wood species and the influence of the toasting process in a very complete way, three approaches should be considered: the volatiles existing in wood itself, the volatile that are extracted into an hydroalcoholic solution in order to avoid matrix effect, and finally the volatiles of wines fermented or maturated with these woods.

Sample preparation methods and chromatography techniques within this purposed has been recently reviewed by Cabrita et al. (2012).

In this work the volatile fraction from woods were studied by GC/MS in acacia (unknown specie), chestnut (Castanea sativa) , cherry (Prunus cerasus) and oak (Quercus robur) chips, subjected to different toasting levels, in order to compare untoasted and medium toasted woods.

To achieve that goal we have used a method based on Pressurized Liquid Extraction (PLE) for the extraction of volatile compounds from wood samples. The PLE, also known as “Accelerated Solvent Extraction” (ASE) was introduced in 1996 (Richter et al., 1996) and is one of the most useful techniques for extraction of non-polar and medium polar solutes from solid and semi-solid samples. Among the extraction methods that use organic solvents, PLE has been proposed as an improved exhaustive extraction method that requires only small volumes of solvents and allows faster and systematic extractions of compounds.

MATERIAL AND METHODS

Chemicals

Dichloromethane, chromatographic grade, and anhydrous sodium sulphate were from Panreac (Barcelon, Spain), diatomaceous earth (ASE® Prep DE) was from Dionex and 3-Octanol was purchased from Extrasyntese (Genay, France). The alcanes mixture, from C7 to C30 was from Supelco Analytical (Bellefonte, USA).

Samples

Wood samples from acacia, chestnut, oak and cherry were provided as chips, untoasted (UT) and medium toast (MT, 2 hours at 200ºC) by JM Gonçalves Cooperage industry. Woods were seasoned in the open air during 25 months for cherry and acacia, 22 month for chestnut and 32 month for oak. Toasting characteristics are protected by industry secret. Botanical species were: oak (Quercus robur) chestnut (Castanea sativa), acacia (unknown specie), and cherry (Prunus cerasus). Acacia is usually Robinia pseudoacacia L., False Acacia or Black Locust, commonly named acacia instead of robinia.

Sample Extraction

Extraction of oak chips was performed by using an Accelerated Solvent Extractor ASE 100 (Dionex, ASE 100). About 3g of exactly weighed wood chips, dispersed in 1.5g of diatomaceous earth, was placed into the sample cell, which was filled with dichloromethane and raised to 150°C. After the selected temperature had been reached, a three times pressurized static extraction phase (7 min) at 20 MPa were carried out.

The obtained extracts (ca 30 mL) were added to sodium sulfate, filtered, and concentrated to approximately 2 mL in an evaporative rotavapor (BUCHI Rotavapor R-114). 3-Octanol (1 mL of 0.08mg/ mL solution) was added as internal standard before concentration. Extraction procedure was based on Natali et al. (2006).

The chips wood samples were previously grounded in a coffee mill into powder, and after this procedure, were extracted as described above. Samples were prepared in triplicate.

GC/MS analysis

A Thermo Finnigan Trace GC gas chromatograph (Thermo Finnigan, Austin, TX), equipped with a Thermo Finnigan Polaris Q mass selective detector was used. Samples (1 μL) were injected in the split-less mode and volatiles were separated using a fused silica capillary column, ZB-Wax 30 m, 0,25 mm i.d and 0,25 μm film thickness (Zebron Capillary GC column; Phenomenex USA) under the following working conditions: GC grade helium as carrier gas at a flow rate (constant flow) of 1.0 mL/ min; column temperature program, 40°C (held 1 min) heated at 4 °C/ min to 100 °C and then heated at 8 °C/min to 250°C (held for 10 min). The injection temperature was 250°C. Detection was carried out by positive ion electron impact (EI) mass spectrometry in the full scan mode, using an ionization energy of 70 eV and a transfer line temperature of 250°C.

The mass acquisition range was m/z 40-450 and the scanning rate 1 scan s-1. Chromatographic peaks were identified by comparing their mass spectra with those reported in the literature and in commercial libraries NIST 2.0 and Wiley 7. The linear retention index values were calculated in the polar column described and also in a apolar column, Rtx-5 (Crossbond 5% diphenil – 95% dimetil polysiloxane) 30 m, 0.25 mm i.d and 0.25 μm film thickness (RESTEK, USA). For each compound, the linear retention indexes calculated were compared with that reported by other authors. Semi-quantitation was carried out from total ion current peak areas according to the internal standard method. Results were expressed as mg of 3-octanol per 100 grams of wood.

RESULTS AND DISCUSSION

Identi?cation of volatile compounds

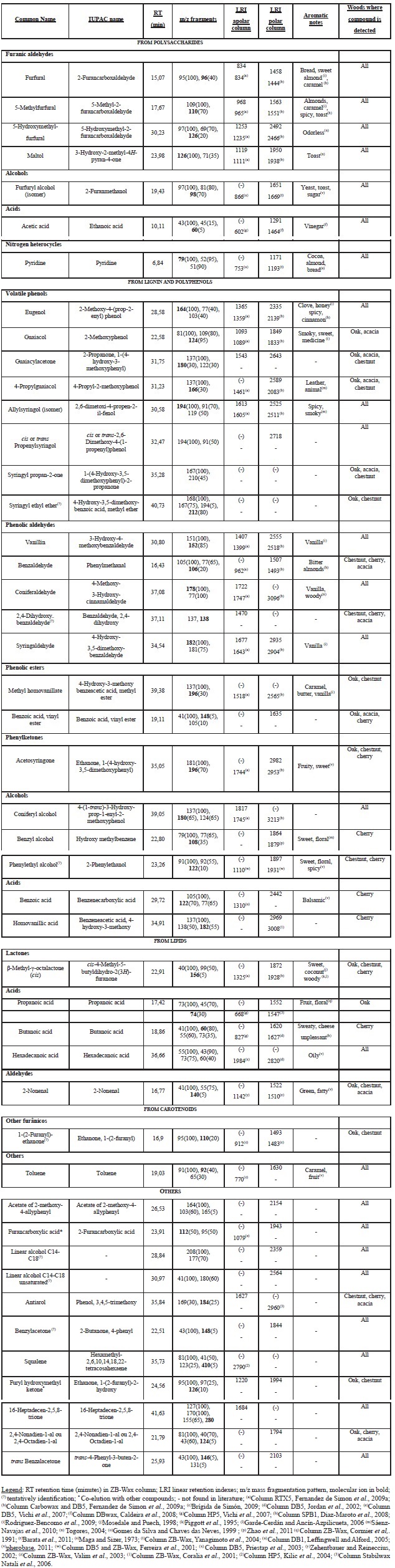

The GC/MS analysis of wood extracts revealed the presence in these woods of several molecules already described in literature. But some compounds not usually referred in literature were also identifi ed. Table I gives the compounds that were identified in at least one sample under study, together with the retention index for columns, their fragmentation pattern and the aromatic notes usually associated with these compounds.

Volatile and semi-volatile compounds found in at least one wood sample

Compostos voláteis e semi-voláteis encontrados em, pelo menos, uma das amostra de madeira.

The chromatograms obtained are very complex and it was observed a series of co-elution, making difficult the identification process, thus resulting in several compounds that remained unidentifi ed. Unequivocally we were able to identified 45 compounds, by comparing their mass fragmentation with those in commercial libraries, and with those reported in literature, also taking into account their retention indexes, structure and molecular weight. Arising from polysaccharides we identified 7 compounds, mainly furanic aldehydes (furfural, 5-methylfurfural, 5-hydroxymethylfurfural and maltol) also reported by several authors (Natali et al., 2006; Vichi et al., 2007). HMF is produced by dehydration of 6-carbon sugars obtained from the hydrolysis of cellulose, while furfural is a result of the dehydration of 5-carbon sugars resulting from the hydrolysis of the hemicellulosic part of woods (Asghari and Yoshide, 2010).

According to Caldeira (2004) there is a positive correlation between furanic aldehydes content and the aromatic descriptors caramel, vanilla and nuts. Hidalgo (2003) and Marín (2005) pointed out almond and toasty notes. Pyridine, not usually mentioned, was also identified, in all samples, although in small amounts. Maga (1985), Nabeta et al. (1986) and Chatonnet (1995) also have mentioned this aromatic nitrogenated compound.

From lignin and polyphenols degradation, we have identified 15 compounds belonging to several chemical families: volatile phenols, phenolic aldehydes, alcohols, phenylketones, phenolic esters and acids, which contribute to vanilla, spicy and smoky notes (Aiken et al., 1984).

Lipids degradation during wood thermal treatments originated lactones, acids and aldehydes. β-metil-γoctalactone is probably the most studied compound in oak woods, with coconut notes attributed to cis and woody notes attributed to trans isomers. Propanoic acid was mentioned by Caldeira et al. (2005) and butanoic and hexadecanoic acids were mentioned by Flamini et al. (2010) for oak wood.

Sixteen other compounds were identifi ed, although their origin is not fully known.

Almost all compounds listed in Table I were already described in literature by several authors, but some compounds are not usually referred such as toluene and pyridine that we were able to identi?ed in all samples.

Influence of the toasting on volatile compounds

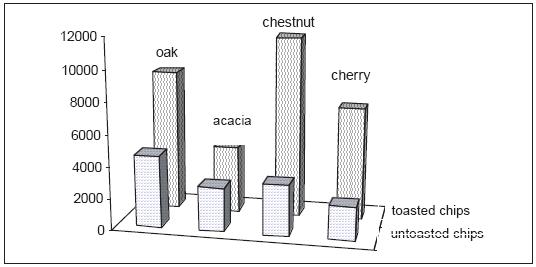

Although 45 compounds were identified and additionally 54 compounds were semi quantified. Untoasted oak presented the higher amount of total volatile compounds (4556.66 mg/100g wood, expressed as 3-Octanol), follow by chestnut (3199.46 mg /100 g wood), acacia (2773.10 mg /100 g wood) and finally cherry (2138.28 mg /100 g wood) (Figure 1). When performing a Tukey-Kramer Multiple Comparison Test for p<0.05, all samples are signifi cantly different before and after toasting, and for toasted samples cherry and acacia are significantly different from oak and chestnut. For untoasted samples chestnut and cherry are different from oak.

Figure 1–Total volatile compounds (mg/100g wood, expressed as 3-octanol); Different letters denote significant difference with 95% confidence level in the Tukey-Kramer Multiple-Comparison Test.

Composição volátil total (mg/100g de madeira, expresso em 3-octanol); Letras diferentes mostram diferença significativas para um nível de confi ança de 95% no teste de comparação de médias de Tukey-Kramer Multiple-Comparison.

The influence of toasting on the total volatile compounds was very significant in chestnut and cherry samples with an increment of over 200%, while in oak we observed an increment of 96% and only of 52% in acacia wood chips. In spite of this differences, all toasted samples are significantly richer on total volatile compounds when compared with untoasted samples by Tukey-Kramer Multiple Comparison Test for p<0.05.

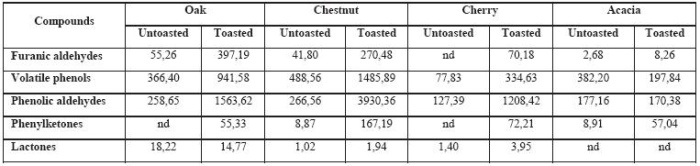

Acetic acid, furfural, 5-methylfurfural, vinyl ester of benzoic acid, maltol, eugenol, vanillin, conyferaldehyde, syringaldehyde, 4-propylguaiacol, acetosyringone, benzyl ketone, guaiacyl ketone, methyl ether of 4-hydroxy-3,5-dimethoxy-benzoic acid, and 16-heptadecen-2,5,8 trione contents increased in all sample submitted to a toasting treatment. Table II shows key chemical families of compounds characterized by GC/MS from oak, acacia, chestnut and cherry wood samples. The results seem to indicate that the botanical species as well as the toasting level influenced the contents of those compounds.

TABLE II

Key chemical families of compounds characterized by GC/MS from oak, acacia, chestnut and cherry wood samples (mg/100g wood, expressed as 3-octanol)

Famílias de compostos químicos caracterizados por GC/MS de amostras de madeira de carvalho, acácia, castanheiro e cerejeira (mg/100g wood, expresso como 3-octanol)

Untoasted woods presented small amounts of furfural, 5-methylfurfural and 5-hydroxymethylfurfural but according to Canas et al. (1999), Caldeira et al. (2006), Jordão et al. (2006), Nonier et al. (2006) and Fernandéz de Simon et al. (2009b) the content increase with toasting. Furfural is the most abundant compound because hemicelluloses are preferentially degradated (Fernandez de Simon et al. 2009a). We could also observed an increase of maltol content with the toasting process for oak and chestnut, in accordance to Fernandez de Simon et al. (2009a). Maltol arises from hexoses degradation in the presence of nitrogen that usually is present, although in small amounts, in woods (Bourgois and Guyonnet, 1988).

Squalene appears to exist in higher amounts in oak chips, while antiarol seems to be characteristic of cherry wood. Although not very often reported in literature, squalene was also found by Alañón et al. (2009) in dichloromethane extracts from oak chips obtained by miniaturised PLE.

CONCLUSIONS

In order to use fragments of woods alternatively to oak it is mandatory to know their chemical composition, namely volatile fraction. The knowledge of the richness of specific wood specie and the influence of the toasting process on its characteristics may be very useful for winemakers when choosing the kind of wood to be used in winemaking or wine maturation. Although this is a first step toward the fully knowledge of these woods, results shows that oak and chestnut are richer than cherry and acacia woods, and that the modifications induced by toasting are the same regardless the wood species. These results are important because although the majority of the compounds are the same, some differences regarding quantity and relative compositions were found, imparting different flavour characteristics to the woods and, hopefully to wines made with them.

REFERENCES

Aiken J.W., Noble A.C., 1984. Comparison of the aroma of oak and glass-aged wines. Am. J. Agric. Food Chem., 35, 196-199. [ Links ]

Alañón M.E., Castro-Vázquez L., Díaz-Maroto M.C., Pérez-Coello M.S. 2012. Aromatic potential of Castanea sativa Mill. compared to Quercus species to be used in cooperage. Food Chemistry, 130: 875-881. [ Links ]

Alañón M.E., Ramos L., Díaz-Maroto M.C., Pérez-Coello M.S., Sanz J., 2009. Extraction of volatile and semi-volatile components from oak wood used for aging wine by miniaturised pressurised liquid technique. Int. J. Food Sci. Tech., 44, 1825-1835. [ Links ]

Arfelli G., Sartini E., Corzani C., Fabiani A., Natali N. 2007. Impact of wooden barrel storage on the volatile composition and sensorial profile of red wine. Food Science and Technology International; 13; 293-299. [ Links ]

Asghari F.S., Yoshida H., 2010. Conversion of Japanese red pine wood (Pinus densiflora) into valuable chemicals under subcritical water conditions. Carbohydr. Res., 345, 124-131. [ Links ]

Barata A., Campo E., Malfeito-Ferreira M., Loureiro V., Cacho J., Ferreira V., 2011. Analytical and sensorial characterization of the aroma of wines produced with sour rotten grapes using GC-O and GC-MS: Identification of key aroma compounds. J. Agric. Food Chem., 59, 2543-2553. [ Links ]

Bourgois J., Guyonnet R., 1988. Caracterization and analysis of torrefi ed wood. Wood Sci. Tech., 22, 143-155. [ Links ]

Brígida de Simón, Esteruelas E., Muñoz A.M., Cadahía E., Sanz M., 2009. Volatile compounds in acacia, chestnut, cherry, ash, and oak woods, with a view to their use in cooperage. J. Agric. Food Chem., 57, 3217–3227.

Cabrita M.J.B., Garcia R., Martins N., Gomes Da Silva M., Freitas A.M.C., 2012. Gas chromatography in analysis of compounds released from wood into wine. In: Advanced Gas Chromatography - Progress in Agricultural, Biomedical and Industrial Applications, pp 185-298. [ Links ]

Cadahía E., Muñoz L., Fernández de Simón B., García-VallejoM.C., 2001. Changes in low molecular weight phenolic compounds in Spanish, French, and American oak woods during natural seasoning and toasting. J. Agric. Food Chem., 49(4), 1790-8. [ Links ]

Cadahía E., De Simón B.F., Jalocha, J., 2003. Volatile compounds in Spanish, French, and American oak woods after natural seasoning and toasting. J. Agric. Food Chem., 51, 5923-5932. [ Links ]

Caldeira I., 2004. O aroma de aguardentes vínicas Envelhecidas em madeira. Importância da tecnologia de tanoria. Tese de doutoramento. Universidade Técnica de Lisboa. Instituto Superior de Agronomia. [ Links ]

Caldeira I., Bruno de Sousa R., Belchior A.P., Clímaco M.C., 2008. Sensory and chemical approach to the aroma of wooden aged Lourinha wine brandy. J. Agric. Food Chem., 23, 97-110. [ Links ]

Caldeira I., Clímaco M.C., Bruno de Sousa R., Belchior A.P., 2006. Volatile composition of oak and chestnut woods used in brandy ageing: Modification induced by heat treatment. J. Food Eng., 76, 202-211. [ Links ]

Caldeira I., Mateus A.M., Belchior A.P., 2005. Flavour and odour profi le modifications during the first five years of Lourinhã brandy maturation on different wooden barrels. Anal. Chim. Acta, 563, 264-273. [ Links ]

Canas S., Caldeira I., Belchior A.P., Spranger M.I., Climaco M.C., Bruno-de-Sousa R. 2011. Chestnut wood: a sustainable alternative for the aging of wine brandies in: Daniel A. Medina D.A. and Laine A.M. (eds.) Food quality: Control, analysis and consumer concerns ISBN: 978-1-61122-917-2 Nova Science Publishers, Inc.

Canas S., Conceição M.L., Spranger L.I., Belchior A.P., 1999. Low molecular weight organic compounds of chestnut wood (Castanea sativa L.) and corresponding aged brandies. J. Agric. Food Chem., 47, 5023-5030. [ Links ]

Chatonnet P., 1995. Influence des procédés de tonnellerie et des conditions d´élevage sur la composition et la qualité des vins élévés en fût de chêne. 268 p. Thèse Doctorat. UFR Institut d´Oenologie, Université de Bordeaux II, Bordéus. [ Links ]

Chatonnet P., 1999. Discrimination and control of toasting intensity and quality of oak barrels. Am. J. Enol. Vitic. , 50, 479-494. [ Links ]

Chatonnet P., Dubourdieu D., 1998. Identification of substances responsible for the “sawdust” aroma in oak wood. J. Sci. Food Agric., 76, 179-188.

Coralia V.G., Siew-Young Q., Ralph J.S., Robert A.W., 2001. Characterization of the bound volatile extract from baby kiwi. J. Agric. Food Chem., 10, 1021-1469c. [ Links ]

Cormier F., Raymond Y., Champagne C.P., Morin A., 1991. Analysis of odor-active volatiles from Pseudomonas fragi grown in milk. J. Agric. Food Chem., 39, 159–161.

Cutzach I., Chatonnet P., Henry R., Dubourdieu D., 1997. Identification of volatile compounds with a “toasty” aroma in heated oak used in barrelmaking. J. Agric. Food Chem., 45, 2217-2224.

Diaz-Maroto M.C., Castro-Várzquez L., De Torres C., Pérez-Coelho M.S., 2008. Aroma-active compounds of American, French, Hungarian and Russian oak woods, studied by GC-MS and GC-O. Flavour Frag. J., 23, 93-98. [ Links ]

Doussot F., De Jeso B., Quideau S., Pardon P., 2002. Extractives content in cooperage oak wood during natural seasoning and toasting; influence of tree species, geographic location and single tree effects. J. Agric. Food Chem., 50, 5955-5961. [ Links ]

Flamini R., Traldi P., 2010. Compounds released in wine from wood. In: Mass spectrometry in grape and wine chemistry, 226240p, John Wiley e Sons, Inc. [ Links ]

Flamini R., Vedova A.D., Cancian D., Pannighel A., Rosso M., 2007. GS/MS- positive ion chemical ionization and MS/MS study of volatile benzene compounds in five different woods used in barrel making. J. Mass Spectrometry, 42, 641-646. [ Links ]

Fernandez de Simón B., Cadahía E., Álamo M., Nevares I., 2009a. Effect of size, seasoning and toasting in the volatile compounds in toasted oak wood and in a red wine treated with them. Anal. Chim. Acta, 660, 211-220. [ Links ]

Fernandez de Simón B., Esteruelas E., Muñoz A.M., Cadahía E., Sanz M., 2009b. Volatile Compounds in Acacia, Chestnut, Cherry, Ash, and Oak Woods, with a View to Their Use in Cooperage. J. Agric. Food Chem., 57, 3217-3227. [ Links ]

Ferreira V., Aznar M., Lopez, R., Cacho J., 2001. Quantitative gas chromatography-olfactometry carried out at different dilutions of an extract. Key differences in the odor profiles of four high-quality Spanish aged red wines. J. Agric. Food Chem., 49, 4818-4824. [ Links ]

Garde-Cerdán T., Ancín-Azpilicueta C., 2006. Review of quality factors on wine ageing in oak barrels. Trends in Food Scien. Technol., 17, 438-447. [ Links ]

Giménez-Martínez R., Garcia de la Serrana H.L., Villalon Mir M., Granados J.Q., Martinez M.C.L., 1996. Influence of wood heat treatment, temperature and maceration time on vanillin, syringaldehyde, and gallic acid contents in oak wood and wine spirit mixtures. Am. J. Enol. Vitic., 47, 441-446. [ Links ]

Gomes da Silva M.D.R., Chaves das Neves H.J., 1999. Complementary use of hyphenated purge-and-trap gas chromatography techniques and sensory analysis in the aroma profiling of strawberries (Fragaria ananassa). J. Agric. Food Chem., 47, 4568-4573. [ Links ]

Hidalgo J. T., 2003. Tratado de enologia (2º vol). 1ª edição. S.A. Mundi-prensa libros. Madrid. [ Links ]

Jordan M.J., Margaria C.A., Shaw P.E., Goodner K.L., 2002. Aroma active components in aqueous Kiwi fruit essence and Kiwi fruit puree by GC-MS and multidimensional GC/GC-O. J. Agric. Food Chem., 50, 5386-5390. [ Links ]

Jordão A.M., Ricardo-da-Silva R.M., Laureano O., Adams A., Demyttenaere J.R.V., De Kimpe V., 2006. Volatile composition analysis by solid-phase microextraction applied to oak wood used in cooperage (Quercus pyrenaica and Quercus petraea): effect of botanical species and toasting process. J. Wood Sci., 52, 514-521. [ Links ]

Kilic A., Hafizoglu H., Kollmannsberger H.E., Nitz S., 2004. Volatile constituents and key odorants in leaves, buds, fl owers, and fruits of Laurus nobilis L. J. Agric. Food Chem., 52, 1601-1606. [ Links ]

Leffingwell J.C.E, Alford E.D., 2005. Volatile constituents of perique tobacco. J. Agric. Food Chem., 4, 899-915. [ Links ]

Maga J.A., 1985. Flavor contribution of wood in alcoholic beverages. In: Progress in fl avour research. Elsevier, 1984, pp. 409-416.

Maga J.A., Sizer C.E., 1973. Pyrazines in foods: a review. J. Agric. Food Chem., 21, 22-30. [ Links ]

Marín F.Z., 2005. Los aromas que el roble aporta al vino; influencia del grado de tostado de las duelas. Unidad de Enología del Centro de Referencia en Tecnología (CeRTA) Departamento de Bioquímica y Biotecnología Facultad de Enología de Tarragona. Universidad Rovira i Virgili. [ Links ]

Mosedale J.R., Puech J-L., 1998. Wood maturation of distilled beverages. Trends in Food Scienc. Technol., 9, 95-101. [ Links ]

Nabeta K., Yonekubo J., Miyake M., 1986. Analysis of volatile constituents of european and japanese oaks. Mokuzai Gakkaishi, 32, 921-927. [ Links ]

Natali N., Chinnici F., Riponi C., 2006. Characterization of vola-tiles in extracts from oak chips obtained by accelerated solvent extraction (ASE). J. Agric. Food Chem., 54, 8190-8198. [ Links ]

Nonier M.F., Vivas N., Vivas de Gaulejac N., Absalon C., Souliè, Ph., Fouquet E., 2006. Pyrolysis-gas chromatography/mass spectrometry of Quercus sp. wood. Application to structural elucidation of macromolecules and aromatic profiles of different species. J. Anal. Appl. Pyrol., 75, 181-193. [ Links ]

Pérez-Prieto L.J., López-Roca J.M., Martínez-Cutillas A., Pardo-Minguez F., Gómez-Plaza E., 2002. Maturing wine in oak barrels. Effects of origin, volume, and age of the barrel on the wine volatile composition. J. Agric. Food Chem., 50, 3272-3276. [ Links ]

Piggott J.R., Conner J.M., Paterson A., 1995. Flavour development in whisky maturation. in Food Flavors: Generation, Analysis and Process Influence, G. Charalambous (Ed.), 1731-1751. [ Links ]

Priestap H.A., Van Baren, C.M., Di Leo-Lira P., Coussio J.D.E., Bandoni A.L., 2003. Volatile constituents of Aristolochia argentina. Phytochem., 63, 221-225. [ Links ]

Richter B.E., Jones B.A., Ezzel J.L., 1996. Accelerated solvent extraction: a technique for sample preparation. Anal. Chem., 68, 1033-1039. [ Links ]

Rodríguez-Bencomo J.J., Ortega-Heras M., Pérez-Magariño S., Gónzalez-Huerta, 2009. Volatile compounds of red wines macerated with Spanish, American, and French oak chips. J. Agric. Food Chem., 57, 6383-6391. [ Links ]

Rosso M., Panighel A., Vedova A.D., Stella L., Flamini R., 2009. Changes in chemical composition of red wine aged in acacia, cherry, chestnut, mulberry, and oak wood barrels. J. Agric. Food Chem., 57, 1915-1920. [ Links ]

Sáenz-Navajas M.P., Campo E., Fernández-Zurbano P., Valentin D., Ferreira V., 2010. An assessment of the effects of wine volatiles on the perception of taste and astringency in wine. Food Chem., 121, 1139-1149. [ Links ]

Togores J.H., 2004. Tratado de enologia Tomo 2. Mundiprensa Ed. [ Links ]

Valim M.F., Rouseff R.L., Lin J., 2003. Gas chromatographic-olfactometric characterization of aroma compounds in two types of cashew apple nectar. J. Agric. Food Chem., 51, 1010-1015. [ Links ]

Van Jaarsveld F.P., Hattingh S., Minnaar P., Blom M., 2008. Rapid induction of ageing character in brandy - effects of extraction media and preparation conditions. S. Afr. J. Enol. Vitic., 30, 1-15. [ Links ]

Vichi S., Santini C., Natali N., Riponi C., Tamames E.L., Buxaderas S., 2007. Volatile and semi-volatile components of oak wood chips analysed by Accelerated Solvent Extraction (ASE) coupled to gas chromatography-mass spectrometry (GC–MS). Food Chem., 102, 1260-1269.

Windeisen E., Wegener G., 2008. Behaviour of lignin during thermal treatments of wood. Industrial Crops and Products, 27, 157-162. [ Links ]

Yanagimoto K., Ochi H., Lee K.G., Shibamoto T., 2004. Antioxidative activities of fractions obtained from brewed coffee. J. Agric. Food Chem., 52, 92-596. [ Links ]

Zhao Y.P., Wang L., Li J.M., Pei G.R., Liu Q.S., 2011. Comparison of volatile compounds in two brandies using HS-SPME Coupled with GC-O, GC-MS and sensory evaluation. S. Afric. J. Enol. Vitic., 32, 9-20. [ Links ]

Zehentbauer G.E., Reineccius G.A., 2002. Determination of key aroma components of Cheddar cheese using dynamic headspace dilution assay. Flavour Fragr. 17, 300-305. [ Links ]

ACKNOWLEDGEMENTS

This work is funded by FEDER Funds through the Operational Programme for Competitiveness Factors - COMPETE and National Funds through FCT - Foundation for Science and Technology under the Strategic Project PEst-C/AGR/UI0115/2011.

* Corresponding author: T. 351 266 769869; F. 351 266 769828, e-mail: mjbc@uevora.pt

(Manuscrito recebido em 24.04.2012. Aceite para publicação em 25.06.2012)