Serviços Personalizados

Journal

Artigo

Indicadores

-

Citado por SciELO

Citado por SciELO -

Acessos

Acessos

Links relacionados

-

Similares em

SciELO

Similares em

SciELO

Compartilhar

Ciência e Técnica Vitivinícola

versão impressa ISSN 0254-0223

Ciência Téc. Vitiv. v.25 n.2 Dois Portos 2010

Grape must mineralization by high pressure microwave digestion for trace element analysis: development of a procedure

S. Catarino1*, I.M.Trancoso1, R. Bruno de Sousa2, A.S. Curvelo-Garcia1

1 Instituto Nacional de Recursos Biológicos I.P./INIA-Dois Portos, 2565-191 Dois Portos, Portugal.

2 UIQA - Instituto Superior de Agronomia, Universidade Técnica de Lisboa, Tapada da Ajuda, 1349-017 Lisboa, Portugal.

SUMMARY

The present work describes the development and validation of a high pressure microwave-assisted mineralization procedure for the determination of metals in grape must by spectrometric techniques. Metals of special oenological and food safety importance (Al, Co, Cu, Cd, Pb) were used as model elements to achieve the optimum working conditions. The study was conducted by monitoring their concentration in experimental samples by ETAAS. Different combinations of HNO3 and H2O2 were tested and an optimal volume of 1 mL of each reagent, added to 2 mL of sample, was selected for further studies. In comparison with experimental conditions described in literature for the mineralization of grape must and wine by HPMW, the proposed procedure requires very low reagent consumption. Time and temperature were regarded as factors in the optimization study of microwave oven program, resulting in 72 minutes of extension including ventilation. The procedure trueness and precision were evaluated using grape must and wine samples. For each element three different levels of addition were performed. The recovery range was from 94% (Co) to 113% (Pb) in grape must and from 96% (Cu) to 128% (Al) in wine. Relative standard deviations ranged from 1% (Cd) to 11% (Al) in grape must and from 2% (Cd, Pb) to 9% (Co) in wine (n = 10). The proposed procedure is suitable for grape must and wine mineralization with a view to trace element analysis.

Key words: grape must, wine, mineralization, high pressure microwave digestion (HPMW), trace element analysis

Desenvovimento de um procedimento de mineralização de mosto para análise elementar, por digestão por microondas

RESUMO

Apresenta-se um procedimento de mineralização de mosto e de vinho, com recurso à técnica de digestão, em vaso fechado, por microondas (sistema de alta pressão), com vista à análise elementar por espectrometria. Na optimização das condições experimentais foram utilizados como elementos modelo metais com especial importância enológica e de segurança alimentar (Al, Co, Cu, Cd e Pb). A determinação analítica destes elementos nas amostras experimentais foi realizada por ETAAS. Foram ensaiadas diferentes combinações de volumes de HNO3 e H2O2 a utilizar na digestão de 2 mL de amostra. O procedimento proposto apresenta baixo consumo de reagentes (1 ml HNO3 e 1 mL de H2O2) comparativamente com os procedimentos de mineralização de mosto por HPMW descritos na literatura. Na optimização do programa de forno do microondas foram considerados os factores tempo e temperatura. A duração total do programa de digestão é de 72 minutos (incluindo a etapa de ventilação).A exactidão e precisão do procedimento foram avaliadas através do cálculo de taxas de recuperação e do coeficiente de variação, respectivamente. As taxas de recuperação, calculadas com base em três níveis de adição de cada elemento, variaram entre 94% (Co) e 113% (Pb) em mosto e entre 96% (Cu) e 128% (Al) em vinho. A precisão variou entre 1% (Cd) e 11% (Al) em mosto e entre 2% (Cd, Pb) e 9% (Co) em vinho (n = 10). O procedimento proposto é adequado para a mineralização de amostras de mosto e de vinho para análise elementar a nível vestigial.

Palavras-chave: mosto, vinho, mineralização, digestão por microondas (sistema de alta pressão), análise elementar vestigial

INTRODUCTION

The elemental analysis of wine is often required from a nutritional, technological, sensorial, toxicological, origin and authenticity point of view (Catarino et al., 2008). The grape must is a complex substance with high organic matrix content, mainly carbohydrates but also organic acids, proteins and polyphenols in much lower concentrations, with large agglomerations of organic matter.

Usually the concentration of sugars in grape must is below 250 g/L. The accurate analysis of grape must and wine elemental content by spectrometric techniques strongly depends on their matrix composition since they can lead to spectral and non-spectral interferences. Thus, a sample pre-treatment is advisable in order to destroy the organic matter that could cause serious interferences in Electrothermal Atomization Atomic Absorption Spectrometry (ETAAS) or Inductively Coupled Plasma Mass Spectrometry (ICP-MS) both suitable for the analysis of elemental content of grape must and wine (Kingston and Walter, 1998; Schlemmer and Radziuk, 1999).

Historically, the preparation of organic samples relied on acid dissolution in an open or closed vessel, with heating applied through the vessel by conduction or convection. Despite their frequent use, hot-plate dissolution procedures are limited by several factors: long dissolution times (hours to days), the potential loss of volatile elements, contamination of the sample by excessive amounts of reagents, airborne contaminants, and prolonged contact with vessel materials. Based on this approach, several procedures using distinct apparatus and experimental conditions were described, and are nowadays used for mineralization of grape berries, grape must and wine (Correia et al., 2006; Laurie et al., 2010).

Microwave digestion offers better performance in the destruction of organic matter in samples with high sugar content, compared to conventional approaches. High pressure microwave assisted digestion (HPMW), which enables sample decomposition at high temperatures without significant losses of volatile elements, is currently the most usually applied digestion technique. This procedure completely destroys the organic matter content of the sample by using concentrated acids. Organic components are oxidized; carbon and hydrogen are converted into carbon dioxide and water. An important advantage is the high throughput, depending on the digestor rotor characteristics. Nevertheless, closed vessel decomposition has a significant drawback: these systems usually limit the sample amount to an only few grams of organic matter.

The most common acid for organic matrices oxidation is HNO3, dissolving most metals to form the soluble metal nitrates. Its oxidizing strength can be enhanced by the addition of H2O2 or by increasing the reaction temperature. Carbohydrates are rapidly decomposed in HNO3 at approximately 140 ºC and for matrices with high concentrations of these easily oxidizable components, the heating rate must be slow to allow safe and under control decomposition (Kingston and Walter, 1998).

The control of the microwave digestion is achieved through combination of temperature feedback control and power settings. Because the reaction is highly exothermic, the contribution of energy depends on the quantity of sample digested and the speed and intensity of the reaction (Kingston and Walter, 1998).

Many applications of microwave digestion for grape, must and wine treatment may be found in the literature data (Teissedre et al., 1993; Puig-Deu et al., 1994; Lopez et al., 1998; Cabrera-Vique et al., 2000; Almeida, 2002; Kristl et al., 2002; Gómez et al., 2004; Capelo et al., 2005; Gromboni et al., 2010). Usually, experimental conditions such as reagents amount or oven program (temperature, time and power) are described without further information on the procedure optimization and validation. Beyond this, we notice remarkable differences between experimental conditions, particularly regarding the reagents combinations and oven programs, without apparent explanation. Only a small part of the experimental conditions diversity could be attributed to the specificities of microwave apparatus. This variety might lead to some confusion about the procedure to apply for sample treatment.

For example, the following conditions were applied by Almeida (2000) in grape treatment by HPMW digestion: 0.90 g dry grapes were attached with 1.5 mL of concentrated HNO3 and 3.5 mL of 30% H2O2. For the same purpose, Kristl et al. (2002) treated 6 g of grapes with 5 mL of concentrated HNO3 and 2 mL of 30% H2O2, while Chopin et al. (2008) treated 0.25 g of grapes with 10 mL of HNO3. As regards to experimental conditions applied for wine mineralization, several reagent combinations are also indicated: 2.0 mL of wine was treated with 2.5 mL of HNO3 and 30 µg of V2O5 (Lopez et al., 1998); 1.5 mL of wine with 0.15 mL of concentrated HNO3 and 1.5 mL of 30% H2O2 (Almeida e Vasconcelos, 1999); 1.5 mL of wine and 8 mL of HNO3 (Esparza et al., 2004).

As previously referred numerous HPMW procedures for the mineralization of grape, grape must and wine may be found in literature. However, to our best knowledge, a complete description of the digestion procedure optimization and validation is not available. Thus, the aim of the present work was to develop and validate a procedure for grape must mineralization by microwave digestion, which can be applied in other laboratories, with a view to elemental analysis by spectrometric techniques. The study was conducted by monitoring the levels of aluminium, cadmium, copper, cobalt and lead, in grape must and wine samples by ETAAS.

MATERIAL AND METHODS

Apparatus

A Milestone ETHOS Plus Microwave Labstation (Milestone, Sorisole, Italy),equipped with a Milestone HPR-1000/6m monoblock high pressure rotor (closed system, maximum operating pressure of 100 bar) with one reference TFM Teflon vessel used for temperature control and five TFM Teflon standard vessels, was used for digestion of the grape must and wine samples.

ETAAS measurements were performed by means of a Perkin-Elmer 4110 ZL ETAAS system (PerkinElmer, Shelton, CT, USA), using Zeeman-effect background correction, equipped with a model AS-72 autosampler and hollow-cathode lamps from Perkin-Elmer as radiation source. Pyrolytically coated graphite tubes with end caps and Lvov platforms were used. Argon (purity > 99,999%) was used to protect and purge the graphite tubes with an internal flow rate of 250 mL/min. The signals were processed in peak area mode. Data process was performed using the Perkin-Elmer AAWinLab software version 2.

Reagents and standard solutions

Ultrapure concentrated HNO3 (J.T.Baker) and Trace Select® 30% (v/v) H2O2 (Fluka, Sigma-Aldrich) were used for digestion optimization procedures.

For ETAAS analysis, monoelement standard solutions of Al, Cu and Pb (10, 20, 30, 40 and 50 µg/L), Co (1.0, 2.5, 5.0, 7.5 and 10 µg/L), Cd (1, 2, 3, 4 and 5 µg/L) were daily prepared from monoelement standard solutions (CertiPUR, Merck, 1000 mg/L), in ultrapure HNO3. Matrix modifiers, graphite furnace grade, of palladium nitrate [Pd(NO3)2] and magnesium nitrate [Mg(NO3)2], both from Merck (10 g/L), were used. Both were injected on the graphite tube with digested samples as follows: 0.5 µg Mg(NO3)2 plus 2.3 µg Pd(NO3)2 for Cd and Pb; 15 µg Mg(NO3)2 for Co, 5 µg Pd(NO3)2 plus 3 µg Mg(NO3)2 for Cu. Al was analyzed without addition of matrix modifiers. All standard solutions were performed in 0.2 % (v/v) nitric acid.

To avoid contamination of the samples, all glassware and polyethylene material (volumetric flasks, micropipette tips and autosampler cups) were immersed at least for 24 hours in 20% (v/v) HNO3 (v/v), and rinsed thoroughly with pure water before use. The reaction vessels were cleaned with 10 mL of a 5% HNO3 solution before each digestion.

For decontamination solution preparation, HNO3 reagent grade was double-distilled using an infra-red subboiling distillatory system (model BSB-939-IR, Berghof, Germany).

Purified water (conductivity < 0.1 µS cm-1) was produced using a Seralpur Pro 90CN apparatus (Seral, Ransbach-Baumbach, Germany).

Sample preparation and MW digestion procedure

The optimization of the microwave digestion oven program (temperature and time) was carried out with a red grape must (Aragonez variety, 2009 vintage year). Grape must was prepared, in the laboratory, by smashing the berries in plastic cups, being the juice transferred to polyethylene tubes. Immediately, a volume of 5 mL of ultrapure HNO3 was added to a sample volume of 45 mL, in order to inhibit the alcoholic fermentation and to start the decomposition reaction.

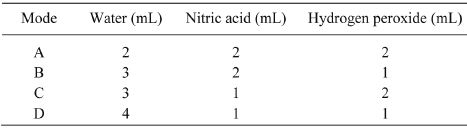

By safe reasons, the amount of organic matter introduced into the digestor vessels used in our experiments should not exceed 1 g. On the other hand, for strong exothermic reactions a minimum volume of 2 mL of water should be used (Milestone, 2009). Thus, a volume of 2.0 mL of grape must (wine) was weighted into TFM Teflon vessels together with different combinations of volumes of HNO3, H2O2 and H2O (Table I), always resulting in a total volume of 8 mL (which is required for the temperature sensor operation). The mixture was allowed to react and after clearance of fumes the vessel was closed. Initial assays were performed to ensure that samples were homogeneous. For contamination control, a blank experiment (treated as a sample) was prepared each run. Blank solutions were regularly analyzed in order to subtract the background signal.

TABLE I

Grape must mineralization by High Pressure Microwave Digestion – reagent combinations used in the procedure development

Mineralização de mosto por Digestão por Microondas (sistema de alta pressão) – combinações de reagentes ensaiadas no desenvolvimento do procedimento

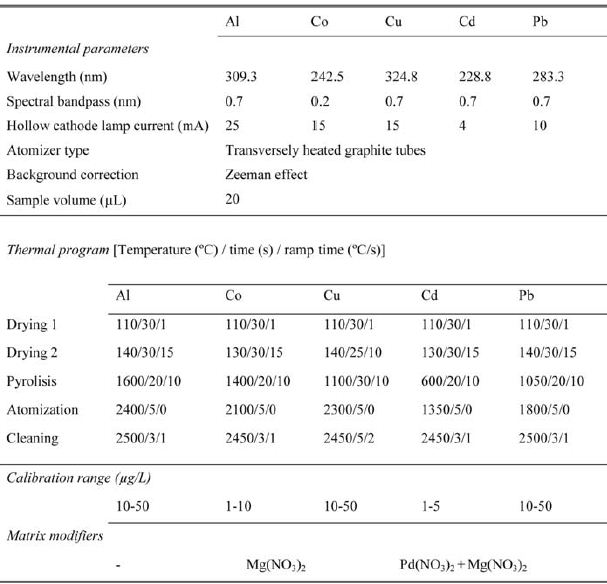

With the purpose of obtain a concentration of each analyte that could be confidently quantified by ETAAS, the natural grape must was spiked with 500 µg/L of Al, Cu and Pb and 50 µg/L of Co and Cd. Concentrations of Al, Co, Cu, Cd and Pb, in all experimental samples, were determined by ETAAS, under the operating conditions indicated in Table II. The overall conditions were previously described by the authors (Catarino, 2000; Catarino et al., 2002, Catarino et al., 2005, Catarino et al., 2009).

TABLE II

Operating conditions employed for Al, Co, Cu, Cd and Pb analytical determination by ETAAS

Condições operatórias utilizadas nas determinações analíticas de Al, Co, Cu, Cd e Pb por ETAAS

Recovery and precision of the MW digestion procedure

To the best of our knowledge, reference grape must and/or wine with certified concentrations of Al, Co, Cu, Cd and Pb elements are not available. For this reason, the trueness of the microwave digestion procedure was estimated by the technique of standard additions to determine recovery of each spiked analyte. Three different fortifications of each element were performed in grape must and red wine before the digestion step and samples processed in the same way as other experimental samples. Depending of the element, samples were spiked with 20-1500 µg/L. The average recovery and standard deviation were calculated from the three recovery values obtained for the three spikes.

The within-batch precision of the digestion procedure was evaluated by ten parallel digestions of the samples. A red wine obtained in the distribution was also used for the evaluation of recovery and precision of the digestion procedure. Concentrations of Al, Co, Cu, Cd and Pb elements were determined in all experimental samples by ETAAS.

Statistical Analysis

Descriptive statistics of the results (namely, average and standard deviation) and analyses of variance (ANOVA) were performed using Microsoft Excel 2007 and Statistica 5.1 data analysis software (Statsoft Inc. 1998).

RESULTS AND DISCUSSION

Optimization of the HPMW program for grape must decomposition

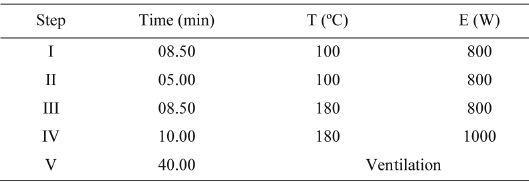

For safety reasons and in order to ensure complete digestion, to minimize the reagents consumption and the production of nitric smoke (yellow-red gases generated), the microwave system chosen was as follows: samples were heated from room temperature up to 100 ºC at 800 W, following a ramp that takes 8.5 min to be completed. This temperature was kept constant for 5 more minutes. Afterwards, the temperature was increased up to 180 ºC at 800 W following a ramp that takes 8.5 min to be completed. This temperature was kept constant for another 10 min at 1000 W. A 40 min ventilation step completed the whole sequence (Table III). The carousel was left overnight and after cooling it was removed from the oven, the vessels were uncapped and samples were diluted to 20 mL with ultrapure water.

TABLE III

Optimized oven program for grape must mineralization by High Pressure Microwave Digestion

Programa de forno optimizado para a mineralização de mosto por Digestão por Microondas (sistema de alta pressão)

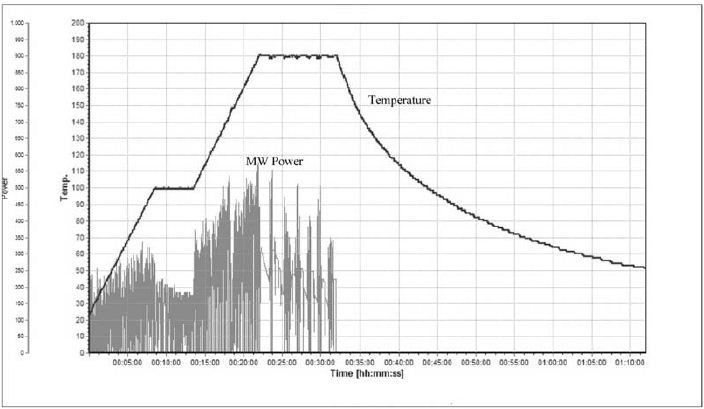

During the course of the digestion, the reaction conditions inside the control vessel were compared to the performance-based protocol. The microwave power was adjusted based on the difference between the prescribed settings and the measured conditions. During the described experiments, temperature feedback control, accurately and safely, controlled the digestion of grape must matrix. The reaction profile of grape must with nitric acid and hydrogen peroxide is shown in Figure 1.

Fig. 1 – Reaction profile (temperature and microwave power) of 2 mL of grape must with 1 mL of HNO3, 1 mL of H2O2 and 4 mL of H2O.

Perfil da reacção (temperatura e potência emitida) de 2 mL de mosto com 1 mL de HNO3, 1 mL de H2O2 e 4 mL de H2O.

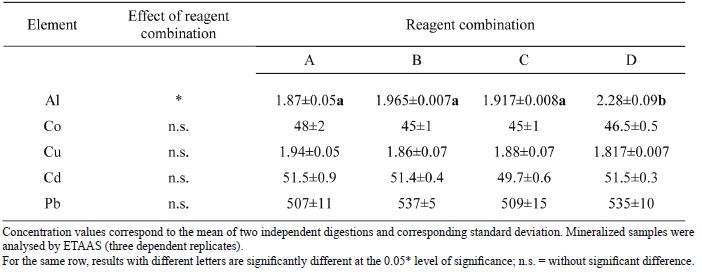

Concerning the elements in study, with exception of Al, no significantly different concentrations were observed between different reagent combinations (P = 0.05) (Table IV). Aluminum concentration was higher when using 4 mL of H2O, 1 mL of HNO3 and 1 mL of H2O2. In this mode smaller volumes of reagents (other than water) are consumed, which is an advantage. Furthermore, for ETAAS analysis, a minimum amount of acids should be used, since high concentrations could significantly reduce the graphite tubes lifetime. Consequently, the mode using 4 mL of H2O, 1 mL of HNO3 and 1 mL of H2O2 was selected.

TABLE IV

Effect of reagent combination used in High Pressure Microwave Digestion procedure on the concentrations of Al, Co, Cu, Cd and Pb in grape must (results for Al and Cu are expressed as mg/L and as µg/L for Co, Cd and Pb)

Efeito da combinação de reagentes utilizados no procedimento de Digestão por Microondas (sistema de alta pressão) nas concentrações de mosto em Al, Co, Cu, Cd e Pb (Al e Cu expressos em mg/L, Co, Cd e Pb expressos em µg/L)

Concentration values correspond to the mean of two independent digestions and corresponding standard deviation. Mineralized samples were analysed by ETAAS (three dependent replicates).

For the same row, results with different letters are significantly different at the 0.05* level of significance; n.s. = without significant difference.

Analytical figures of merit

Aluminium, Cu and Pb blank digestion concentrations, before correction of the dilution factor (1:10), were 2.4, 2.9 and 0.27 µg/L, respectively. The levels of Co and Cd were lower than the detection limit of the corresponding analytical method (0.37 and 0.05 µg/L). It can be concluded that the procedure is suitable for sample preparation with a view to trace analysis.

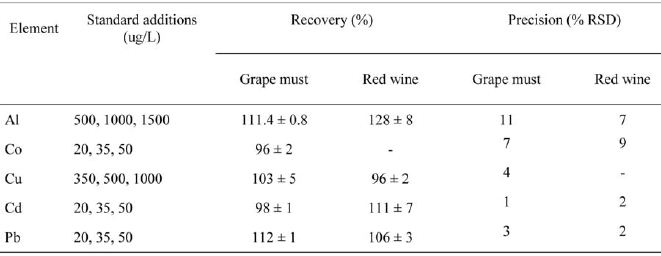

The results concerning recovery and precision tests are presented in Table V. Regarding the Al element the average percentage recovery was of 111% for grape must and of 128% for wine, suggesting the occurrence of contamination during analytical process, despite all the efforts taken. For Co element the average percentage recovery was of 96% (grape must). By practical reasons it was not possible to carry out similar study with wine. Recovery percentages very close to 100% were observed for Cu element: an average value of 103% for grape must and an average value of 96% for wine. Concerning Cd element an average recovery of 98% was found in grape must and a higher value, 111%, in wine. For Pb element, recovery percentages higher than 100% were observed in grape must (112%) and red wine (106%). Assuming as acceptance criterion for overall recovery (mineralization procedure and analytical determination), between 80% and 120%, the results are satisfactory, with exception of Al in wine sample.

TABLE V

Recovery percentages and precision by element obtained in grape must and wine samples mineralized by High Pressure Microwave Digestion

Taxas de recuperação e precisão, por elemento, determinadas em amostras de mosto e vinho mineralizadas por Digestão por Microondas (sistema de alta pressão)

Ten replicates of digestion of each sample type (grape must and red wine) gave relative standard deviations between 1% and 11% (n = 10), indicating that the microwave mineralization procedure is of high precision (Table V). The relative standard deviation values obtained for Al (11% and 7% for grape must and wine, respectively) and Co (7% and 9% for grape must and wine, respectively) are explained by the low concentrations of these elements both in grape must and wine. Concerning Cu element, the precision in wine was not determined because the natural concentration of Cu in this sample was lower than the quantification limit of the analytical method.

CONCLUSIONS

The procedure proposed for sample mineralization by high pressure microwave digestion can be used to the treatment of grape must and wine, in view to trace analysis by spectrometric techniques. It provides a number of advantages, such as rapid and complete mineralization of the sample without analyte losses and/or additional contamination and a high throughput. A very important advantage is the very low consumption of reagents. On the other hand, the low concentration of acids in treated samples enables its analysis by ETAAS (with no compromise of graphite tubes lifetime) or ICP-MS, without any further dilution. It can be concluded that some of the experimental conditions described in literature for the mineralization of must grape and wine, in particular the amounts of acids used for sample oxidation, are probably overestimated. Concerning the metals used as models, the precision and recovery of the procedure are satisfactory (with exception of Al) and in agreement with the required quality of the analytical results for characterization and comparison purposes.

ACKNOWLEDGEMENTS

The authors are particularly grateful to the Fundação para a Ciência e a Tecnologia for financial support (PTDC/AGR-ALI/64655/2006).

REFERENCES

Almeida C.M.R., Vasconcelos M.T.S.D., 1999. UV-irradiation and MW-digestion pre-treatment of Port wine suitable for the determination of lead isotope ratios by inductively coupled plasma mass spectrometry. Journal of Analytical Atomic Spectrometry, 14 (12), 1815-1821.

Almeida C.M.R., 2002. Isotopic and multi-element characterisation of wine for identification of lead contamination sources and of the provenance region. Doctoral thesis, 252 p. Faculdade de Ciências da Universidade do Porto, Porto.

Cabrera-Vique C., Teissedre P.L., Cabanis M.T., Cabanis J.C., 2000. Manganese determination in grapes and wines from different regions of france. American Journal of Enology and Viticulture, 51 (2), 103-107.

Castiñeira M.M., Brandt R., von Bohlen A., Jakubowski N., 2001. Development of a procedure for the multi-element determination of trace elements in wine by ICP-MS. Fresenius Journal of Analytical Chemistry, 370, 553-558.

Catarino S.C.G., 2000. A ocorrência de chumbo e cádmio em vinhos. MSc Thesis, University of Porto, Porto.

Catarino S., Curvelo-Garcia A.S., Bruno de Sousa R., 2002. Determination of aluminum in wine by ETAAS: Validation of Analytical Method. Atomic Spectroscopy, 23 (6), 196-200.

Catarino S., Pimentel I., Curvelo-Garcia A.S., 2005. Determination of copper in wine by ETAAS using conventional and fast thermal programs: Validation of Analytical Method. Atomic Spectroscopy, 26 (2), 73-77.

Catarino S., Curvelo-Garcia A.S., Bruno de Sousa R., 2008. Elementos contaminantes nos vinhos (a review). Ciência e Técnica Vitivinícola, 23 (1), 3-19. [ Links ]

Catarino S., Neves A., Bruno de Sousa R., 2009. Determination of cobalt in wine and must by ETAAS: Analytical method development and validation. Ciência e Técnica Vitivinícola, 24 (2), 65-72. [ Links ]

Capelo J.L., Catarino S., Curvelo-Garcia A.S., Vaião M., 2005. Focused ultrasound versus microwave digestion for the determination of lead in must by electrothermal-atomic absorption spectrometry. Journal of AOAC International, 88 (2), 585-591.

Chopin E.I.B., Marin B., Mkoungafoko R., Rigaux A., Hopgood M.J., Delannoy E., Cancès B., Laurain M.J., 2008. Environmental Pollution, 156, 1092-1098.

Correia L., Soares M.E., Bastos M.L., 2006. Validation of an Electrothermal Atomization Atomic Absorption Spectrometry Method for the determination of aluminum, copper and lead in grapes. Journal of Agricultural and Food Chemistry, 54, 9312-9316.

Esparza I., Salinas I., Caballero I., Santamaría C., Calvo I., García-Mina J.M., Fernández J.M., 2004. Evolution of metal and polyphenol content over a 1-year period of vinification: sample fractionation and correlation between metals and anthocyanins. Analytica Chimica Acta, 524, 215-224.

Gómez M.M.C., Brandt R., Jakubowski N. Andersosn J.T., 2004. Changes in the metal composition in german white wines through the winemaking process. A study of 63 elements by inductively coupled plasma – mass spectrometry. Journal of Agricultural and Food Chemistry, 52, 2953-2961.

Gromboni C., Carapelli R., Pereira-Filho E.R., Nogueira A.R.A., 2010. Evaluation of different sample preparation procedures using chemometrics: comparison among photo-fenton reaction; microwave irradiation, and direct determination of mineral in fruit juices. Food Analytical Methods, 3 (2), 98-103.

Kristl J., Veber M., Slekovec M., 2002. The application of ETAAS to the determination of Cr, Pb and Cd in samples taken during different stages of the winemaking process. Analytical and Bioanalytical Chemistry, 373, 200-204.

Kingston H.M.S., Walter P., 1998. The art and science of microwave sample preparations for trace and ultratrace elemental analysis. In: Inductively Coupled Plasma Mass Spectrometry. 33-81. Montaser A. (ed.), Wiley-VCH, USA.

Laurie V.F., Villagra E., Tapia J., Sarkis J.E.S., Hortellani M.A., 2010. Analysis of major metallic elements in chilean wines by atomic absorption spectrometry. Ciência e Investigación Agrária, 37 (2), 77-85.

Lopez., F., Cabrera C., Lorenzo M.L., Lopez M.C., 1998. Aluminium levels in wine, beer and other alcoholic beverages consumed in Spain. The Science of Total Environment, 220, 1-9.

Milestone, 2009. ETHOS 1. User manual. Rev. 4/2008. Milestone Microwave Laboratory Systems, Italy.

Puig-Deu M., Lamuela-Raventós R.M., Buxaderas S., Torre-Boronat C., 1994. Determination of copper and iron in must: Comparison of wet and dry ashing. American Journal of Enology and Viticulture, 45 (1), 25-28.

Schlemmer G., Radziuk B., 1999. Analytical Graphite Furnace Atomic Absorption Spectrometry. A laboratory guide. 286 p. Birkhauser Verlag, Basel, Switzerland.

Teissedre P.L., Cabanis M.T., Cabanis J.C., 1993. Comparison of two mineralization methods for determination of lead by electrothermal atomic-absorption spectrometry – application to soils, vine-leaves, grapes, must grapes and lees samples. Analusis, 21 (5), 249-254.

* Corresponding author: Sofia Catarino.

Instituto Nacional de Recursos Biológicos I.P./INIA- Dois Portos, 2565-191 Dois Portos, Portugal.

Tel.: +351 261 712106; Fax: +351 261 712426;

e-mail address: sofia.catarino@inrb.pt

(Manuscrito recebido em 10.11.10 . Aceite para publicação em 21.12.10)